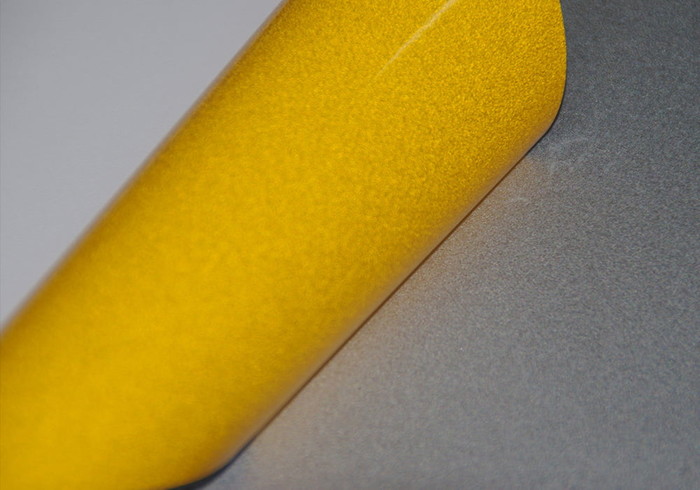

Reflective sheeting is a specialized material commonly used in road signs, vehicle markings, and other applications where visibility and safety are critical, particularly in low-light conditions or at night. It is designed to enhance the visibility of objects by reflecting incident light, such as from vehicle headlights, back towards the light source. The specific product parameters you've mentioned for reflective sheeting are important for determining its suitability for different applications. Here's a breakdown of these parameters:

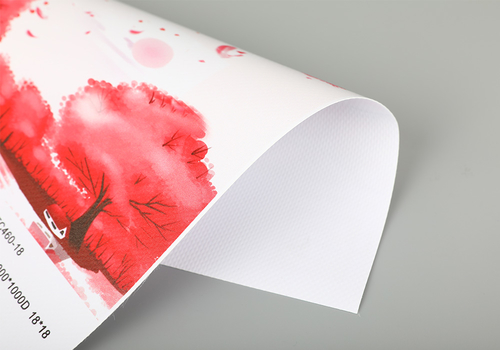

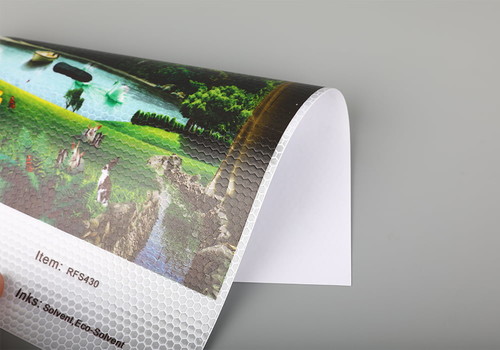

Surface Film: Reflective sheeting typically comes with a surface film made from different materials. The options include:

PET (Polyethylene Terephthalate): PET is a durable, transparent plastic that provides good resistance to environmental factors.

Acrylic: Acrylic film offers optical clarity and weather resistance, making it suitable for outdoor applications.

PVC (Polyvinyl Chloride): PVC film is known for its flexibility and durability, often used in outdoor signage.

Film Thickness (MM): Reflective sheeting is available in different thicknesses to meet various durability and application requirements. The thickness options you've mentioned are 0.11mm, 0.10mm, and 0.16mm. Thicker films are typically more robust and durable.

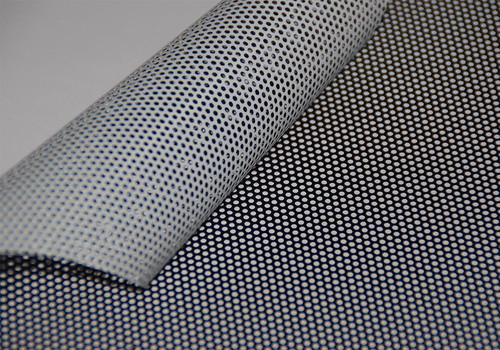

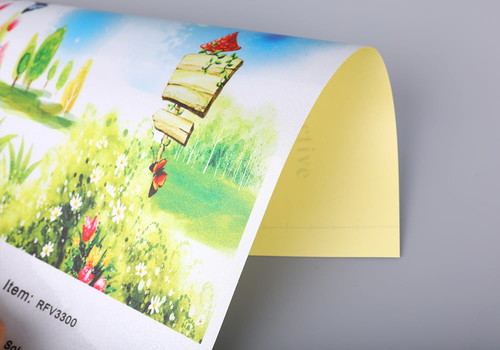

Liner (g/m2): The liner is a backing or support layer for the reflective sheeting. It provides structural integrity and ease of handling. A liner weight of 120 g/m2 suggests a moderately sturdy backing.

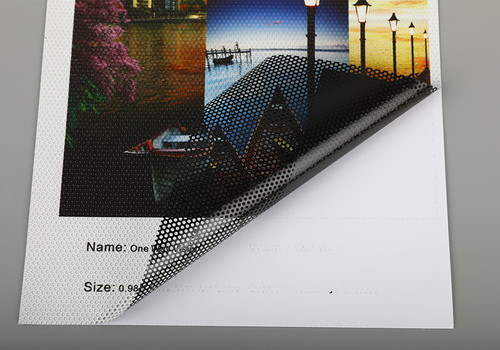

Glue: Reflective sheeting is usually backed with adhesive to facilitate its application. The options include:

Clear Adhesive: Clear adhesive is transparent and is often used when the reflective sheeting needs to adhere to a surface without affecting its color.

White Adhesive: White adhesive may be used when a white background is desired, which can enhance the sheeting's color reflectivity.

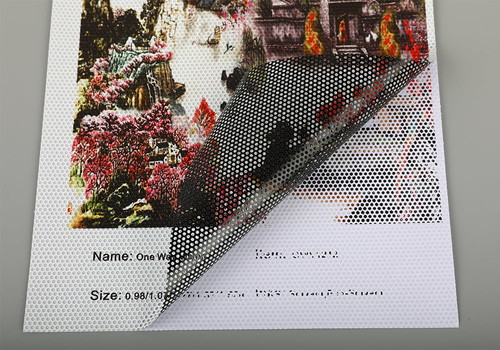

Width (M): Reflective sheeting is available in different widths to suit various applications. Common width options are 1.22 meters and 1.24 meters.

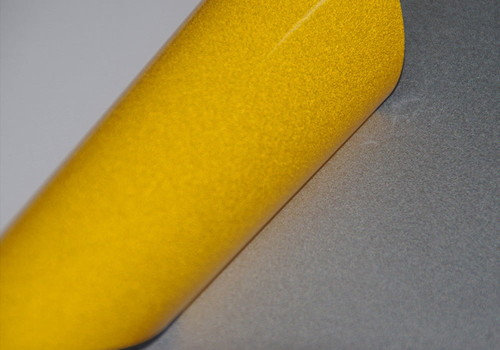

Color: Reflective sheeting comes in various colors to meet different visibility and aesthetic needs. The color options you've mentioned include white, yellow, red, green, blue, orange, and black. The choice of color is critical, especially for road signs and safety markings, as it affects the sheeting's visibility and message conveyance.

In summary, reflective sheeting is a versatile material with customizable parameters to suit various applications. Its main function is to enhance visibility and safety by reflecting incident light, and the choice of film type, thickness, adhesive, width, and color depends on the specific requirements of the intended use.